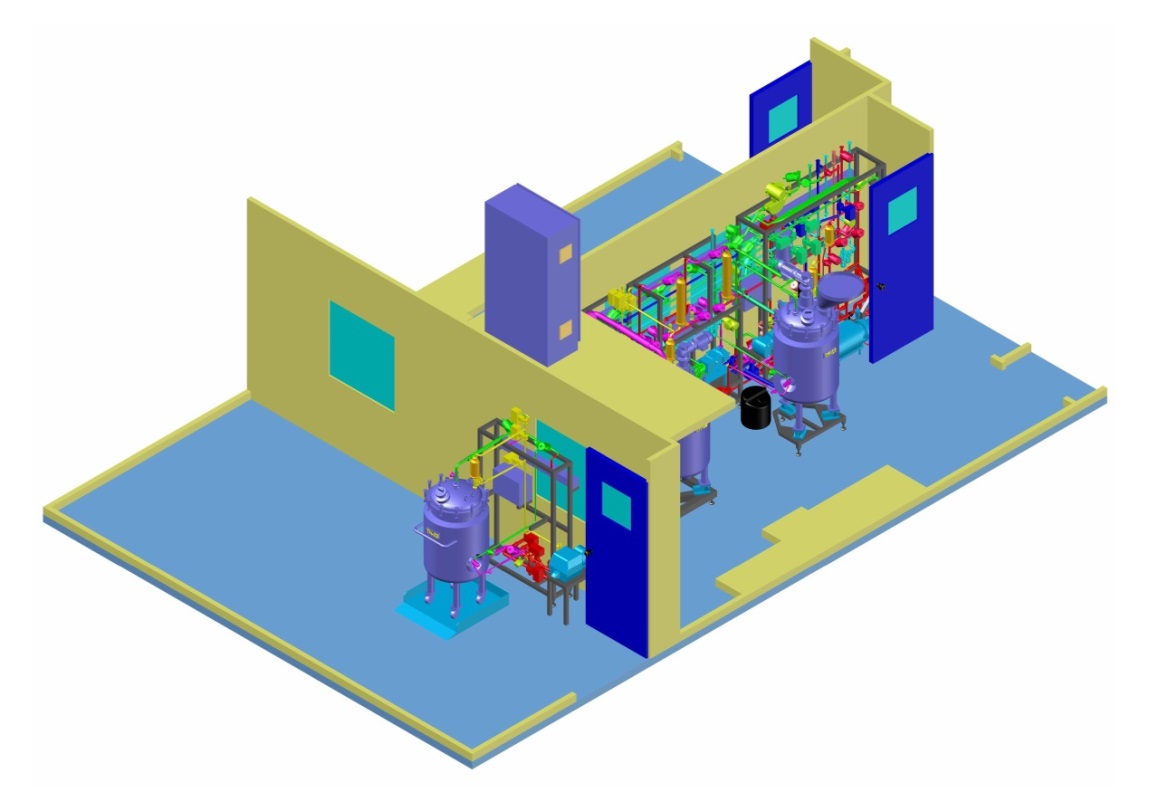

Immuno-modulator production line project case

The production line in this case is applied for Biological macromolecular products. The membrane separation technique which include depth filtration and tangential flow filtration is applied in this production line, in which the automatic production equipment is adopted.

Customer-made design is adopted from bulk extraction to sterile production, ie. from reactor , depth filtration, ultrafiltration to sterile filtration.

The paperless production information and the visualization of the production process are in accordance with the development trend of the biological macromolecular production process.、