Home > Events >BFS(Blow-Fill-Seal)Extrusion Molding

BFS(Blow-Fill-Seal)Extrusion Molding

|

BFS

technology is an advanced technology for producing the plastic-packaged

preparations, by which the whole process of blowing, filling and sealing can

be completed at once under a sterile environment. Compared to the conventional

filling lines, it has great advantages. However, due to the complexity of

such equipment, more factors will affect the product quality, in which the

plastic bottle molding problem is the most prominent one. The plastic bottle molding is affected by various factors, such as plastic performance and melting temperature, vacuum setting, compressed air pressure setting, cooling setting, equipment maintenance level, device operation motion setting parameters as well as the experience of operators. Firstly, this article aims to seek the best extruding temperature through the experiment of adjusting the temperature of the extruder so as to guarantee the quality of the plastic bottle molding. Secondly, this article details analysis on the factors causing the abnormal bottle molding and provides corresponding solutions. At last, this article provides the suggestions how to guarantee the stable operation of production, how to improve the product percent of pass and how to reduce the production cost.

Extruder Temperature Experiment l Equipment &

Materials BFS-310

equipment manufactured by Tofflon has been adopted to conduct the contrast

experiment, which can produce 30 2ml bottles at once, with the production

capacity of 9000 bottles/ hour. The plastics particles selected in this

experiment is 3020D low density polyethylene (LDPE) produced by BASELL, a

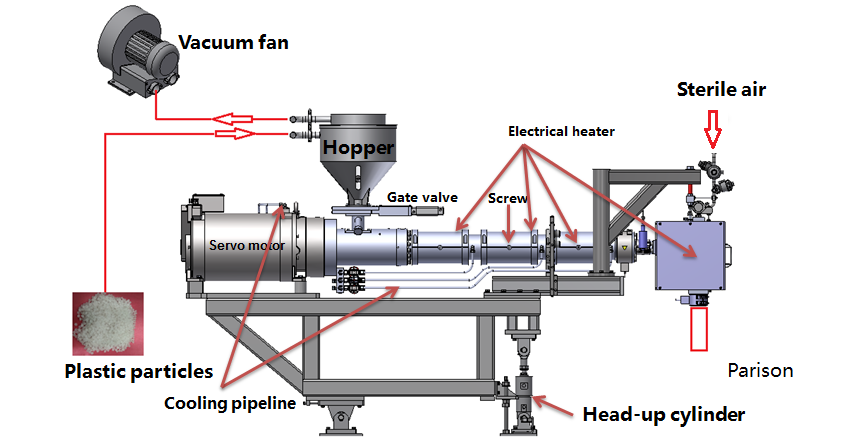

German company. l Experiment Method The

plastic particles are put into the hopper on top and then get melted. After

that, the melted liquid goes through the screw and is pushed into the die, in

which a set of 30 bottles is blow-molded. The drug liquid is transported from

the preparation room to the overhead of the system through pipelines. After

the empty bottles are cooled inside the die, the drug liquid is injected into

the bottle through multi-head filling port, and then the bottles get sealed.

After the whole process of blowing, injection and sealing have been

Data

on bottle shapes tested under different extruding temperatures.

Reasons

for Causing Abnormal Bottle Molding and The Corresponding Solutions From

the data of the experiment results, it can be analyzed that 3020D presents

the relatively data within the temperature range of 70℃~175℃. When the temperature within this range increases appropriately,

the melt fluidity speed increases and the bottle wall thickness will have a

slight increase correspondingly. In the actual operations, there will be more factors to affect the bottle molding. Besides the extruding temperature, the defected bottle molding can also be related to the stability of the equipment and the operation skills of the operators. The defected bottle molding is the main problem to lower the percent of pass. Simultaneously, it is also of great importance to correctly set the equipment parameters and well grasp the technology standard. In addition, the defected bottle molding and the protective machine halt will not only reduce the yield coefficient, but also, more importantly, bring environmental risks since the human intervention will affect the aseptic conditions. The table below shows the analysis on the reasons of causing the abnormal bottle molding and provides the detailed adjustment solutions.

In

addition to the extruding system, there is another important factor to

influence the percent of pass of the bottles, and that is, the die. After the

extruder produced the qualified tube billet, die is the most important place

for bottle molding. The bottle shape design, the temperature control, the

vacuum control, the installment, and the clamping pressure control of the die

will all have effect on the molding quality of the bottles. |