Home > Events >Visual Inspection of Parenteral Products Part 3: Defect Prevention vs Removal QA vs QC

Visual Inspection of Parenteral Products Part 3: Defect Prevention vs Removal QA vs QC

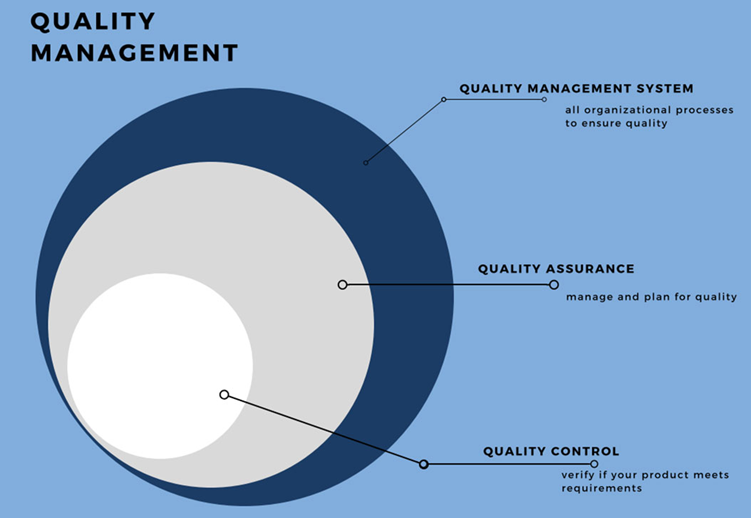

Quality is the degree to which a set of inherent characteristics of an object fulfill requirements ,according to ISO 9001:2015.

Quality

Assurance and Quality Control are separate parts of the Quality Management

System (QMS)

Quality

Assurance

The planned and systematic activities

implemented in a quality system so that required quality standard for a product

or service can be fulfilled.

QA is therefore proactive in its nature and it

is targeted in designing and managing all production processes in such a way to

reduce as much as possible the occurrence of defects and problems in

manufactured products.

Quality

Control

The procedure or set of procedures intended to

ensure that a manufactured product or performed service adheres to a defined

set of quality criteria or meets the requirements of the client or customer.

QC is therefore reactive in its nature; it is

targeted to find and remove from production stream all products which are not

compliant with quality requirements.

It is extremely important to highlight that

while this document is entirely

management of the whole production and Quality Assurance (QA) process are likewise essential to reduce as much as possible any cause of defective or contaminated products in the first place.

Neither

QA or QC process alone can guarantee 100% good results

They should always work together to help each other to achieve the most effective and stable results on final product quality.

QA and QC – A balance critical to achieve Product Quality

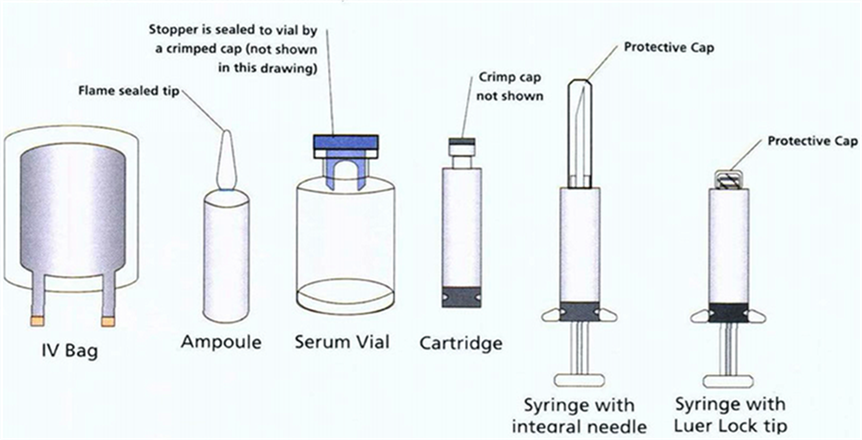

Quality Control in Parenteral

Main inspection/quality items to be checked. After the introduction of QC

and QA concepts we’ll start now diving more in detail about quality control in

parenteral products and which main quality aspects are regulated by main

pharmacopeias and are commonly checked worldwide.

There are obviously important differences and changes in time and among

different countries, however we can list the following most important

categories of visual controls in parenteral products.

·

Visible particles

·

Container Closure Integrity

·

Other visible defects (cosmetic)

·

Additional container defects

We already discussed in part 2 how the most critical aspect to be

controlled before releasing the products to the market and to the final users

is the safety of the product, then it comes its proper function and finally

come minor defects as cosmetic or appearance.

The safety of products can be harmed by two main problems:

- the

presence of foreign particles into the container, especially extrinsic

(see part 2), which by definition implies the lack of sterility

- the

lack of integrity of the container so that microorganisms from outside can

enter and contaminate the product

According to these

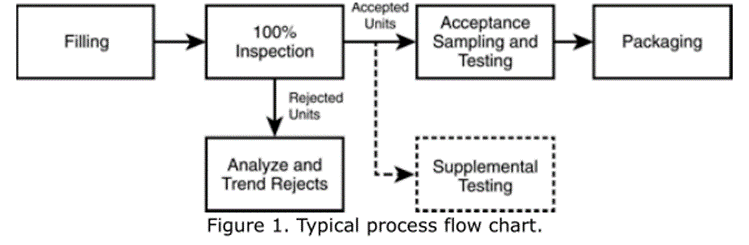

principles, the most important visual controls performed on 100% of production

are for particles and closure of container.

The other controls (filling level, cosmetic, etc.) are usually performed at the same time but are less critical and receive less attention and resources.

Regulations, Definitions & Guidelines About Visible

Particles

Starting in 1942 when the USP and the American Pharmaceutical Association (publisher of the National Formulary at that time) stated that aqueous injections should be “substantially free” of particles discernible with the naked eye, the definition eventually evolved into those currently used by the three major Pharmacopeias stating that injectable drug products should be “essentially free” (USP), “practically free” (European Pharmacopeia) or free of “readily detectable” (Japanese Pharmacopeia) visible particles.

Most recent requirements

require each and every unit of injectable product to be inspected as part of

the routine manufacturing process (100% inspection).

It is recommended to

execute inspection where defects can most easily be spotted, for example before

labeling.

Each unit can be examined

manually by unaided eye (Manual Visual Inspection or MVI) or by using a

conveyor system to transport and present the containers to a human inspector

(Semi-automatic inspection) or by means of Automatic Visual Inspection (AVI)

machine.

Manual and semi-automatic

inspection should only be performed by trained, qualified inspectors.

The intent of this inspection is the detection and removal of any observed defect. When in doubt, units should be removed.

Notes: 100% inspection refers to the complete inspection of the container+closure system and its content.

Requirements

from main Pharmacopeias

- EP

requires “Practically free” of visible particles

- USP

requires “Essentially free” of visible particles

- JP

requires “free from readily detectable foreign insoluble matters”

For a very long time this kind of unclear –

nonobjective requirements have put drug manufacturers in a difficult position.

However recently, the FDA and the other regulatory agencies have moved forward

to make requirements and procedures more standardized, clear and easy to

fulfill and assess.

After several enhancements and harmonization

processes to make all pharmacopeias more similar, the regulation is currently

based on three main steps:

- The

manufacturing processes and associated controls are designed to yield a

product free from visible particles to the extent possible.

- Visual Inspection (100%)

is performed at the end of drug product manufacturing

- Visual

Inspection is followed by sampling inspection (AQL sampling) to confirm

the “Essentially free” requisite before releasing the batch to the market.

Regulations,

definitions & guidelines about Container Closure Integrity (CCI)

Similarly, to requirements for visible particles, the three main pharmacopeias contain general requirements about integrity of closure and are subject to a process of evolution through time and common harmonization.

·

USP “The packaging system should be closed or sealed in

such a manner as to prevent contamination or loss of contents”

· 21 CFR “Container closure systems shall provide adequate protection against foreseeable external factors in storage and use that can cause deterioration or contamination of the drug product”

·

JP “Hermetic containers or tight containers which

are able to prevent microbial contamination are usually used for the

preparations”

·

EP “The tightness of the container is ensured by suitable

means. Closures ensure a good seal, prevent the access of micro-organisms and

other contaminants and usually permit the withdrawal of a part or the whole of

the contents without removal of the closure”

As we will see more in detail in the next part,

the CCI testing can be

nowadays performed by visual inspection and by

other non-visual technologies (high voltage, pressure decay, laser adsorption, etc.).

Consequently, current regulations focus more on

the result and the validation of the whole process regardless of the specific

inspection system/technology used.

It is therefore required to first evaluate and assess the risk of lack of integrity and take every possible measure to prevent its happening (QA approach). Then it is required to take the best possible approach to detect and reject from production all containers whose integrity is not guaranteed(QC approach).