Home > Events >Tofflon Max-Fill Medium/High-Speed 100%IPC Check Weighing Vial Filling Machine

Tofflon Max-Fill Medium/High-Speed 100%IPC Check Weighing Vial Filling Machine

Novel vaccines (genetically engineered vaccines, combined vaccines, live attenuated vaccines, therapeutic vaccines for major infectious diseases, etc.), biotherapeutic and genetically engineered drugs (cell therapy, biological monoclonal antibodies, etc.), large molecule drugs, blood products, slow/controlled release complex injections (emulsions, liposomes, microspheres, etc.), and antineoplastic products are innovative drugs with very high added value and requirements for the relevant performance indicators of aseptic filling equipment.

In

recent years, filling technology has been an essential part of production lines

for aseptic injection filling processes. Many high value-added injection drugs

are required to meet high standards and requirements during the filling

production process. How to achieve the stability and reliability of high

value-added pharmaceutical filling accuracy, implement automatic calibration of

the filling volume in the filling system with minimal or even zero loss of

medicinal liquid in the production preparation stage, ensure no filling volume

drift during the filling process and achieve the process quality control of

100% filling volume, and empty the tailings to minimize the residue and

material loss at the end of the filling production or reduce material loss to

the volume of even one vial with the emptying mode are severe risks and

challenges of traditional filling technology in the guarantee of many key

processes.

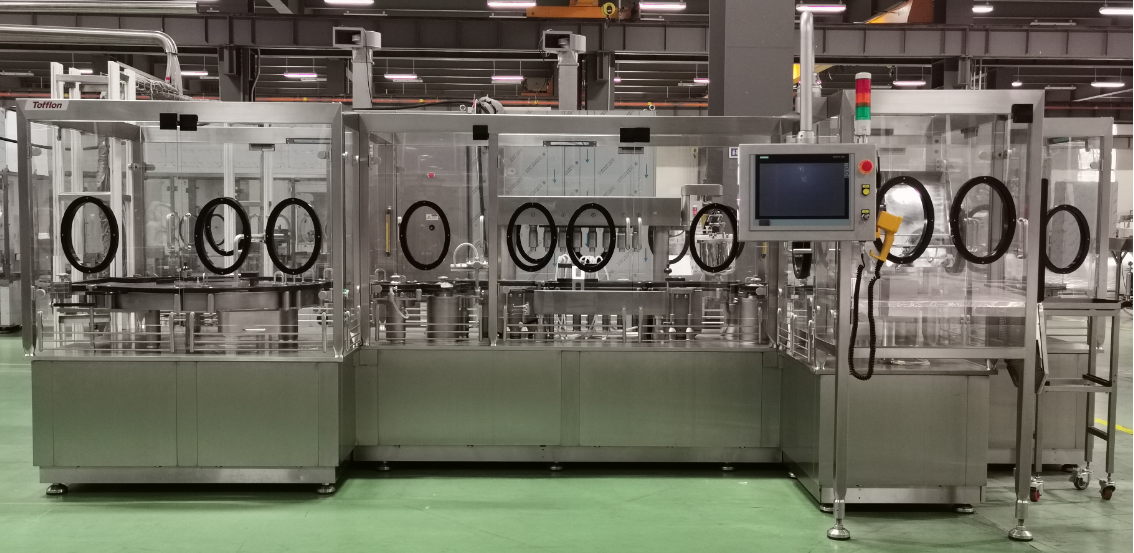

Max-Fill 100% IPC medium/high-speed check weighing vial filling machine is pharmaceutical filling equipment in direct contact with medicines. It affects the quality of medicine in the production directly and is the crucial equipment in aseptic preparation filling production lines. The innovative filling system design defines a new quality standard for the Max-Fill 100%IPC medium/high-speed check weighing vial filling machine. The device allows full-automatic detection (100% control) without loss of yield or productivity. It can thoroughly perform 100% medium/high-speed online quality control under different production modes before, during, and after production, striving to achieve the filling without product loss at start-up or near clearing of product loss. Hence, the filling yield of medicine is improved to guarantee the high added value entirely and effectively.

300 vials/min medium/high-speed 100% IPC check weighing vial filling line

Medium/high-speed 100% IPC check weighing vial filling machine

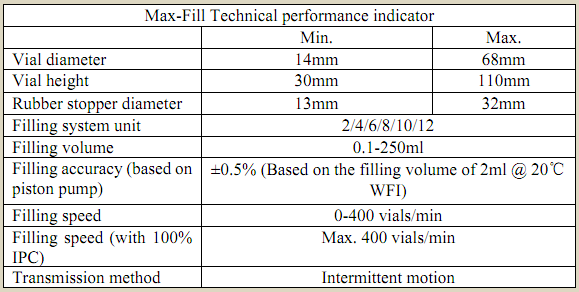

Max-Fill Technical Performance Indicators

Max-Fill Host Features and Advantages

Comply with

cGMP, EU-GMP and FDA regulations

Outstanding

industrial aesthetic design, excellent human-machine interface

GMP concept

aseptic design, easy to clean, operate and maintain

Diversified

layout: single-sided operation, double-sided operation, L-shaped layout,

I-shaped layout

Advanced multi-link linear servo transmission system that ensures gentle and stable conveyance of vials

No filling or

stoppering without vial

Three

independent output channels: qualified products, sampling and kick-off channels

Toolless

plug-in type quick-change mold specifications

Restricted

barrier system that can be integrated with the following: oRABS, cRABS and

Isolator

Control system

compliant with GAMP 5 and 21 CFR Part 11

Batch records

and reports that meet the computerized system requirements

Max-Fill Important Configuration Options

Filling system that can be integrated with CIP-SIP system

Nitrogen filling system (nitrogen charging before

filling-during filling-after filling-stoppering)

Various filling or compound filling methods such as

piston pump-peristaltic pump-time pressure method

Can be integrated with 100% IPC medium and high-speed

check weighing system

Each filling system is independently driven and

controlled by a servo motor to adjust the filling volume automatically

“Advanced filling” operation mode under different production modes

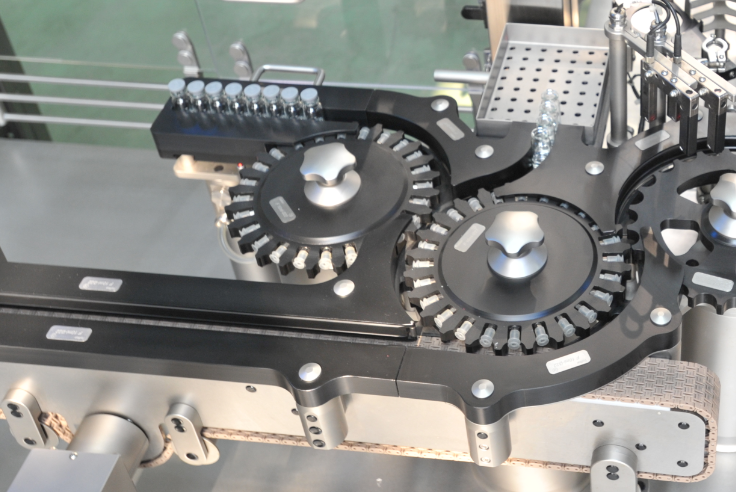

Infeed Star-wheel System

100% IPC Check Weighing System

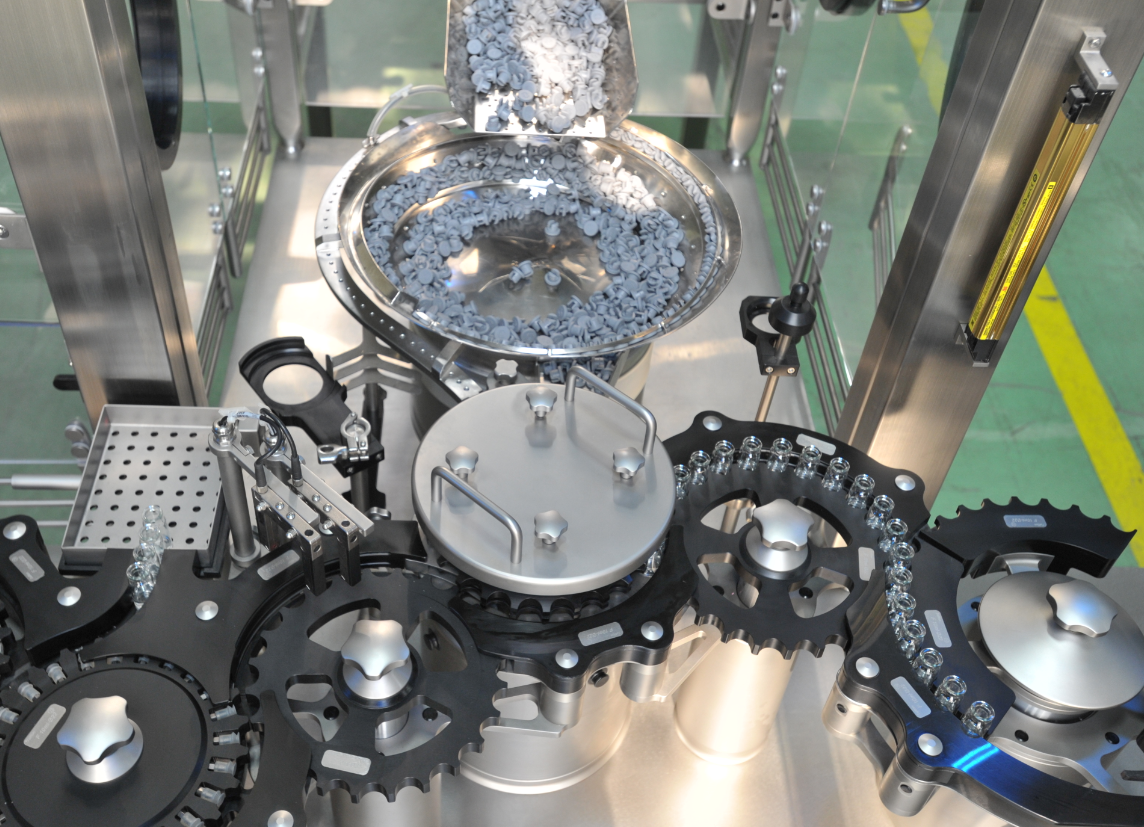

Stoppering System

Peristaltic Pump Filling System

Discharge Star-wheel System