Home > Events >

Probiotics is essential in human’s daily life, and probiotic products in solid form are generally produced by freeze-drying/lyophilization.

The main quality indicator for probiotic products is the quantity of live bacteria during the validity period. Tofflon is dedicated to exploring

the maximization and automation of probiotics production capacity and efficiency while ensuring quality indicators.

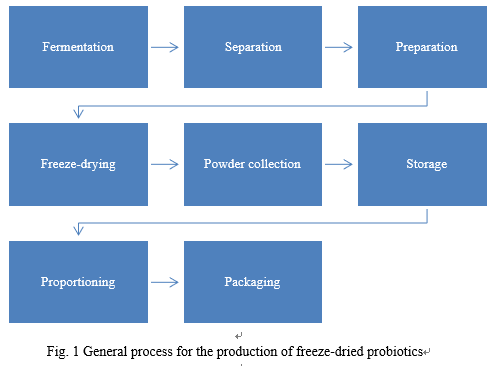

General process for the production of freeze-dried probiotics

The general process for the production of freeze-dried probiotics is as follows:

A good probiotic strain is identified for culture and screening, and the fermentation is scaled up to the industrial scale through the fermenter.

-

The bacterial

sludge is mixed with the protectant in a preparation tank to obtain a

suspension containing probiotics.

-

The

suspension is filled on the lyophilizer shelf, freezing, vacuuming, heating and

drying on the shelf until the endpoint is reached. The lyophilizer restores to

normal pressure. Open the door to remove the freeze-dried powder.

-

The

freeze-dried powder is collected into a closed container and

-

placed in

cold storage for storage.

-

When

proportioning production is needed, the stored bacterial powder bin is removed

from the cold storage for quantitative feeding, proportioning and mixing

through the proportioning and mixing system. After the mixing is processed, the

proportioning bin is connected to the packing machine for the dispensing of

finished products. Eventually, the dispensed products are packaged and then

released in the market.

-

The bacterial

sludge is mixed with the protectant in a preparation tank to obtain a

suspension containing probiotics.